In today’s rapidly evolving energy landscape, the oil and gas industry faces numerous challenges. Operators must strive to maximize productivity while also minimizing their environmental impact. To address these complex issues, Adaptive Process Solutions (APS) Company, based in Aberdeen, Scotland, has developed an innovative technology that promises to revolutionize the oil and gas sector. With a strong commitment to sustainability, APS Company has harnessed cutting-edge adaptive process solutions to enhance productivity and reduce the environmental footprint of oil and gas operations.

The aging infrastructure of oil and gas assets, coupled with the need to meet stringent environmental regulations, presents a significant challenge for operators in the industry. One pressing issue they face is the effective and efficient cleaning of produced water before its discharge back into the sea. Recognizing this industry-wide concern, APS has developed an innovative solution known as the Microbubble Infusion Unit (MiFU).

The MiFU technology offers a breakthrough approach to address this challenge, providing operators with a reliable and sustainable method for cleaning produced water. By utilizing microbubbles, the MiFU unit enhances the efficiency of water treatment processes while minimizing environmental impact. This cutting-edge technology not only improves oil and gas productivity but also ensures compliance with strict regulatory standards.

With its ability to significantly reduce costs associated with traditional methods and improve operators’ environmental footprint, APS’s Microbubble Infusion Unit is revolutionizing how aging assets and reservoirs are cleaned in an increasingly environmentally conscious world.

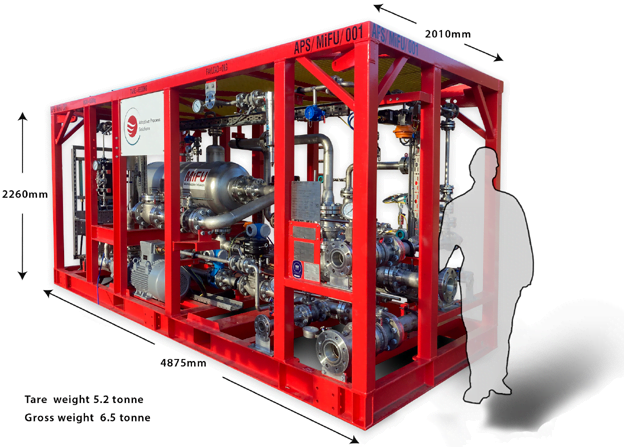

The APS MiFU stands as a remarkable technological advancement, demonstrating its capability to process a substantial volume of water, ranging from 1000 to 100,000 barrels per day. A standout feature of this innovative system is its ability to efficiently remove up to 90% of oil and contaminants from produced water without necessitating downstream filtration.

Historically, gas flotation technology has been a stalwart in the treatment of produced water, the water co-produced with crude oil. However, despite its long-established status, the application of this technology in numerous existing oil production facilities has seen little change over decades, leaving it in a state that no longer aligns with contemporary requirements.

The crux of the matter lies in the evolving landscape of oil production. Many aging reservoirs are presently grappling with a significant shift, with up to 90% water cut and only 10% oil, a stark contrast to the initial drilling stages when the ratio was closer to 10% water cut and 90% oil. The result is that the small separation systems initially designed to handle lower volumes of produced water have become outdated and ill-suited for the current demand.

In this context, the APS MiFU emerges as a game-changer, addressing the shortcomings of traditional gas flotation technology. By efficiently handling the larger volumes of produced water associated with the changing dynamics of reservoirs, it not only meets but exceeds the requirements of today’s oil production facilities. This forward-looking technology is poised to revolutionize the treatment of produced water, offering a sustainable and effective solution for the challenges posed by evolving reservoir conditions.

The introduction of aps’s Microbubble Infusion Unit (MiFU) has proven to be a significant breakthrough in addressing the industry-wide issue faced by operators of ageing assets and reservoirs. With the pressing need to efficiently and effectively clean produced water before its discharge back into the sea, MiFU has emerged as a game-changer for oil and gas productivity. By utilizing cutting-edge technology, MiFU not only enhances operators’ capabilities to meet strict regulatory standards but also significantly improves their environmental footprint.

The advanced microbubble infusion process ensures that produced water is thoroughly cleansed from contaminants, rendering it safe for marine discharge. Furthermore, by incorporating MiFU into their operations, operators can achieve increased efficiency in treating produced water while reducing their reliance on traditional, resource-intensive methods.